For over 50 years TOOLGAL has provided the highest quality industry standard and custom made Diamond tools for

many industries.

TOOLGAL products combine in-depth metallurgical knowledge, innovative engineering capabilities, wide application

experience as well as flexible and advanced manufacturing capabilities, allowing us to create a wide range of tailor

made solutions for customers around the world.

TOOLGAL’S superior Quality System reduces equipment, material, and human variance factors, ensuring consistent

quality products and processes.

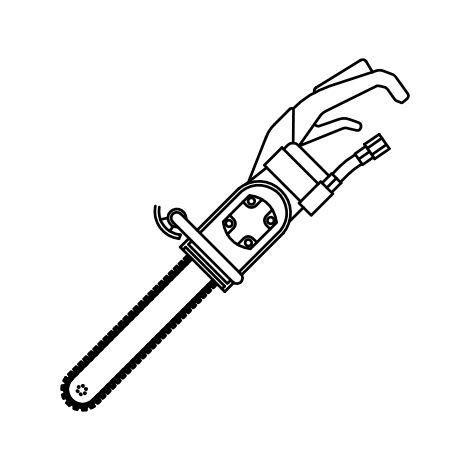

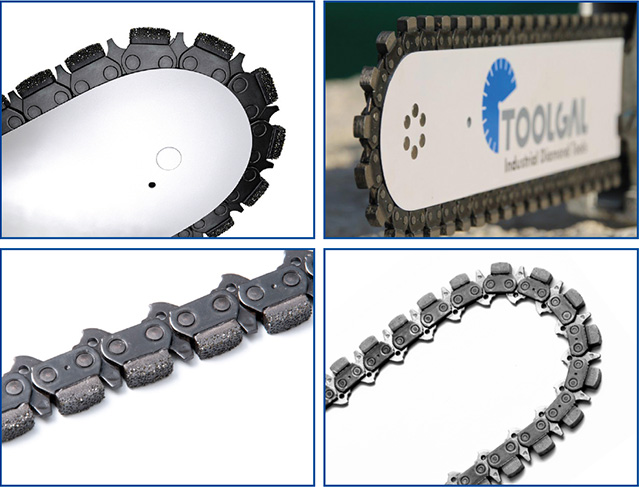

SUPERIOR PERFORMANCE LASER WELDED DIAMOND CHAIN FOR:

- General building materials

- Firebrick/ Refractories

- Reinforced concrete

- Stone /Granite

- Block/ Sandstone/ Abrasive materials

- Coal

- Building Bricks

- Ductile iron/ Cast iron/ PVC/ HDPE

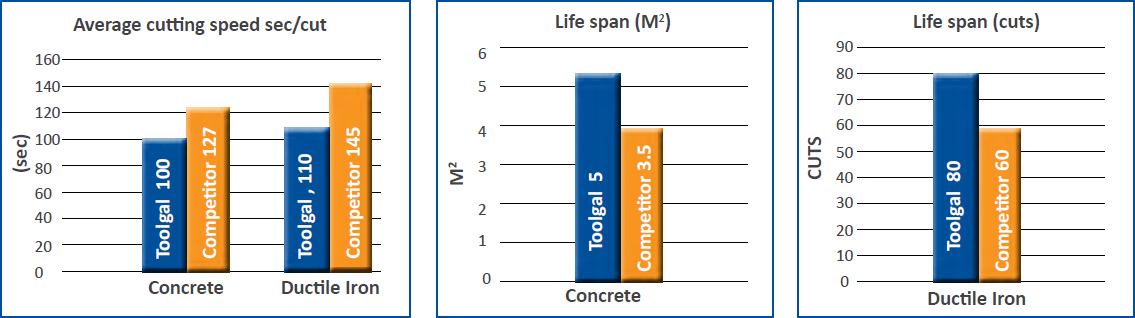

SPEED – 25% faster than others.

LIFE SPAN – 25% longer life span than others.

IMPROVED USER EXPERIENCE – On each link there is a segment providing smoother cutting and higher output. Diamond segment on each link providing smoother cutting, higher output and less vibration.

BULK CONCEPT – Efficient stock management solution: cut to size and repair capability.

COMPLETE KIT – Provides a compatible answer for most common chain cutting machines.

ACCESSORIES – Compatible high quality guide bars, sprockets and chain parts.

TECHNICAL SUPPORT – Direct from the manufacturer.

Toolgal Chains – This is your ultimate alternative for the most efficient way to cut through a wide

range of building materials and utility pipes.

Toolgal offers a variety of diamond chains to meet your cutting needs for the perfect combination

of accuracy and productivity

Ductile Iron testing workpiece: Ductile iron tube 250mm.

Concrete testing workpiece: 0.20m x 0.25m reinforced concrete with 2 x 10mm steel bars.

DESIGNED FOR HEAVY DUTY USE

Choosing the right chain for the project is essential in achieving the best value.

Superior performance laser welded Diamond chain for:

- General building materials

- Reinforced concrete

- Block/ Sandstone/ Abrasive materials

- Building Bricks

- Firebrick/ Refractories

- Stone /Granite

- Coal

- Ductile iron/ Cast iron/ PVC/ HDPE

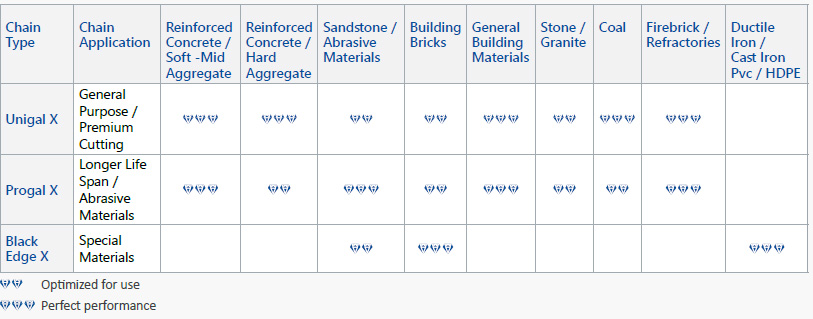

Available in three configurations to match your specific application and cutting challenges:

UniGal X – Best choice for cutting general construction materials and light reinforced concrete

ProGal X – Professional choice for Heavy duty jobs in reinforced concrete and abrasive materials

Black Edge X – Toolgal unique technology for cutting Ductile Iron and Cast iron tubes, construction bricks, PVC and HDPE

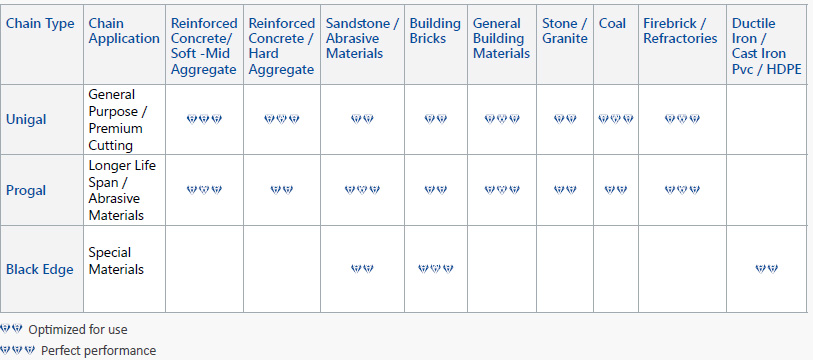

Choosing the right chain for the project is essential in achieving the best value.

Superior performance laser welded Diamond chain for:

- General building materials

- Reinforced concrete

- Block/ Sandstone/ Abrasive materials

- Building Bricks

- Firebrick/ Refractories

- Stone /Granite

- Coal

- Ductile iron/ Cast iron/ PVC/ HDPE

Available in three configurations to match your specific application and cutting challenges:

UniGal – Best choice for cutting general construction materials and light reinforced concrete

ProGal – Professional choice for Heavy-duty jobs in reinforced concrete and abrasive materials

Black Edge – Toolgal unique technology for cutting Ductile Iron and Cast Iron pipes, construction bricks, PVC and HDPE pipes

ADVANTAGES

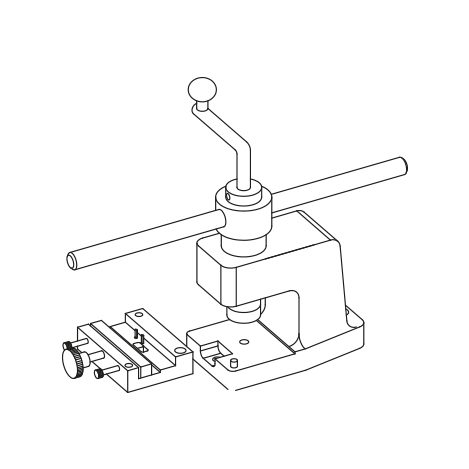

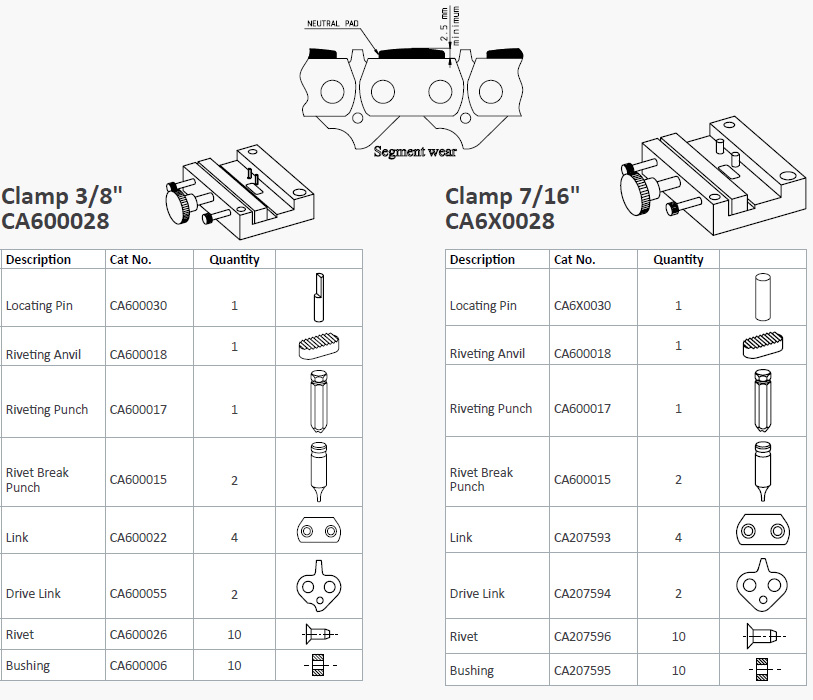

• Cut To Size – Custom build your chain according to the amount of links needed

• Repair capability – Conveniently fix or replace faulty links

• Flexibility and efficient stock management – No need to keep large amounts of various chain sizes in stock.

The efficient assembly kit gives you total flexibility to mount a new chain or repair a broken link, where and when you need to

• Lower logistic costs – Don’t waste valuable time, receive remote assembly training, repair or replace links on site

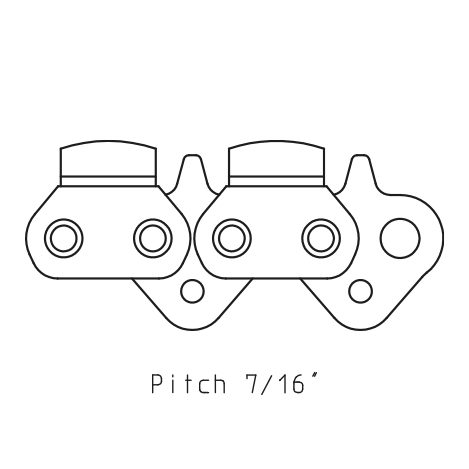

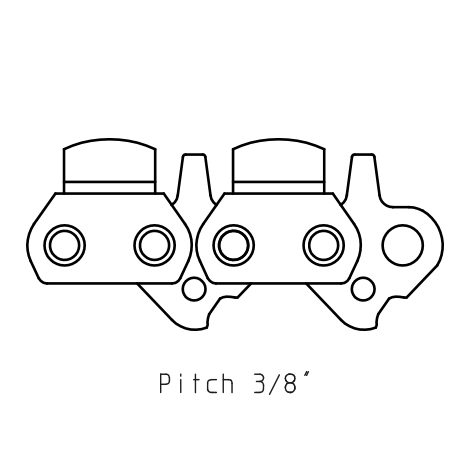

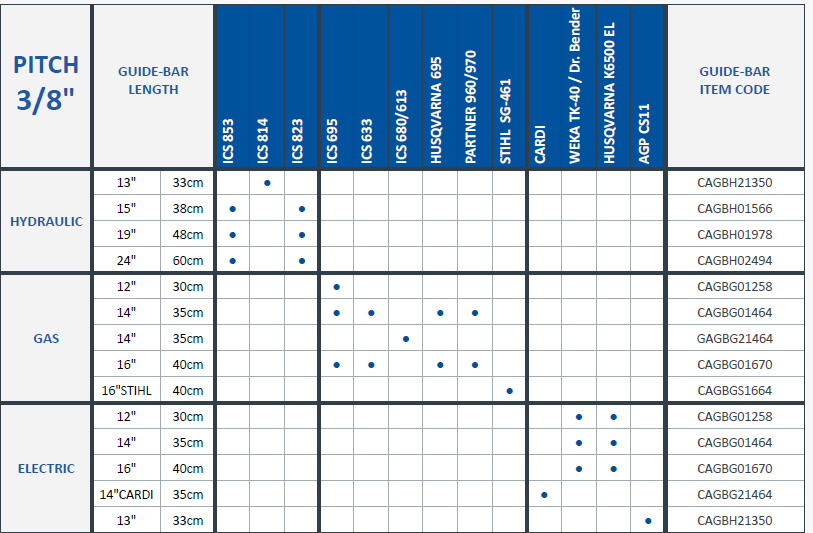

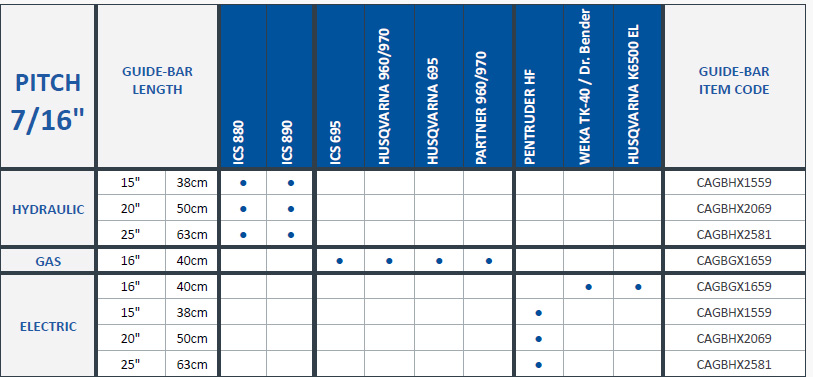

DETERMINE YOUR CHAIN: TYPE 3/8″ or 7/16″

FIND AVAILABLE GUIDE-BAR FOR YOUR POWER CUTTER MODEL

What is the standard guide bar life?

We recommend making a guide-bar inspection after each chain’s replacement.

Guide-bar life depends on the cutting conditions:

• For general construction materials & concrete with light reinforcement: Change a guide bar after using 2-3 chains.

• For concrete with heavy reinforcement: change a guide bar after using 1-2 chains.

• For cast & ductile iron pipes with black edge chains: Change a guide bar after using 1-2 chains

What is the standard diamond chain life?

The chain life depends on cutting conditions.

Each chain type’s life is different and depends on many factors, such as :

• Experience of the operator

• Aggregate type and concrete hardness

• Type of reinforcement. For example: 66 links chain – total output = 3.0-4.0 Sqm

What maintenance should be done at the end of the day ?

• Clean bar& chain with water & dry

• Inspect drive sprocket for teeth wear – replace if needed

• Spray used bar& chain with lightweight oil

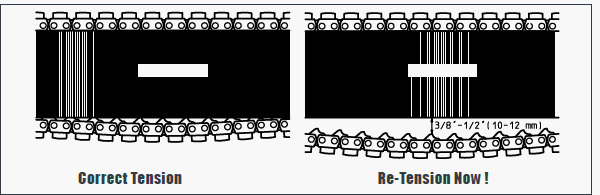

When you should tension the chain?

Important ! Check the chain tensioning before each cut:

• if drive links hanging below the bar up to 10-12mm = > proper tensioning

• if drive links hanging below the bar above 12mm => tension the chain

• after tensioning check that the chain rotates free by pulling it easily around the bar by hand