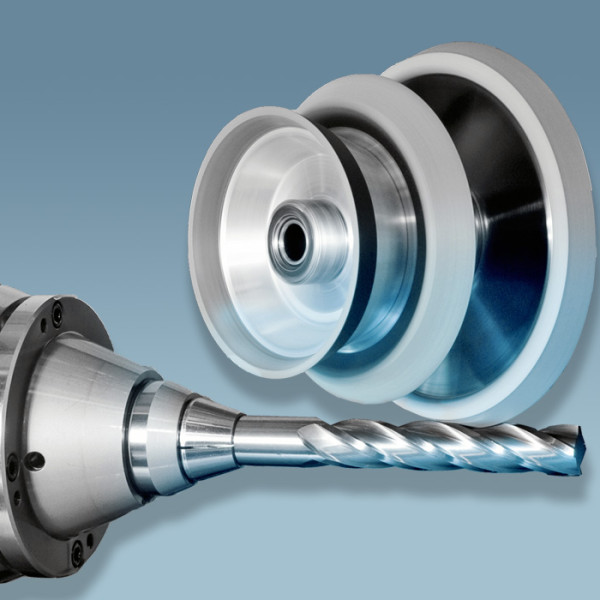

Flute grinding is a most demanding and time-consuming operation, owing to the high stock removal– a cutting depth of 7-8 mm is not unusual. The large contact area makes it difficult for the coolant to reach the grinding zone; thus, excessive heat is generated which could cause damage to the work piece surface and/or reduce the particle strength of the heat-sensitive diamond grits.In order to remain competitive, today’s leading tool manufacturers must achieve high productivity and repeatability, and produce high-quality i.e. excellent finishing products at the lowest possible cost.

Flute grinding is one of the most costly manufacturing steps for mill, drill and cutter manufacturers, hence the need for constant improvement.

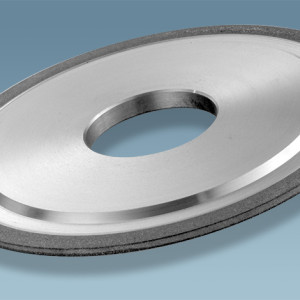

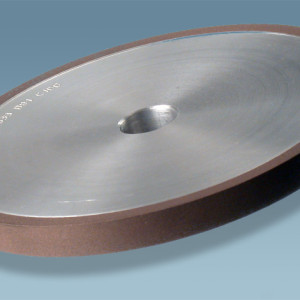

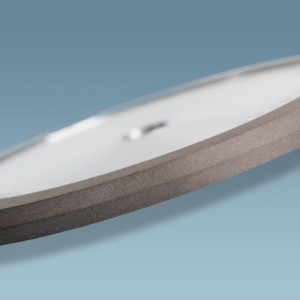

In the engineering of its RM series 5, 6, 7 for flute grinding wheels have proven highly successful in dealing with these requirements. Furthermore, the wheels maintain their profile shape throughout the entire grinding process, leaving a very good surface finish.

The RM series—with its improved bond system and new types of abrasives—presents a wide range of benefits:

- High material removal rates

- Low wheel wear

- Low cutting forces

- Low machine power consumption

- Low frictional heat in the contact zone

- Excellent surface finish and edge quality

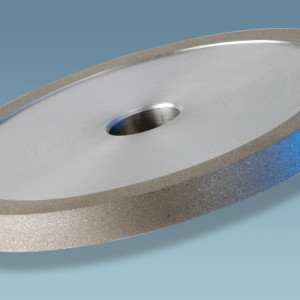

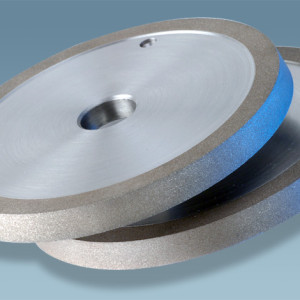

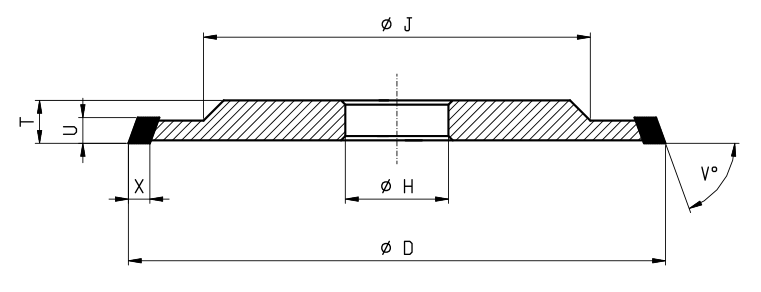

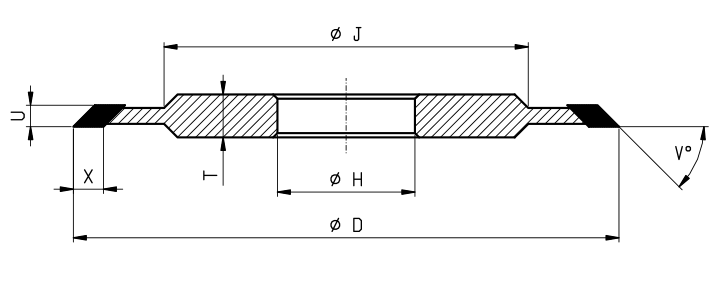

As a result of the above engineering efforts, the Toolgal RM is a highly cost-effective product. It can be supplied off-the-shelf as per standard program, or custom-made as per specific customer requirements (see parameter drawing).

See our stock program below for details.

RM6/7 Recommended for deep and long production runs(QW 6.7)

RM501/515 Recommended for standard production run (QW 4)

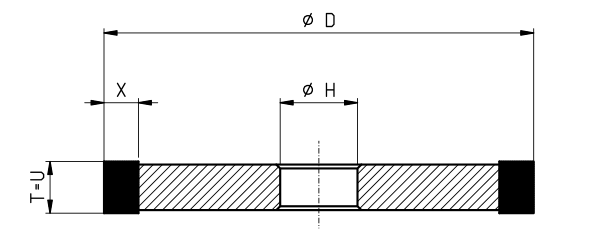

1A1

| D Ø | T | X | X | Diamond | CBN | |

| 50 | 6,8,10 | 6 | 10 | RM5 | RM6/7 | RM9 |

| 75 | 6,8,10,12,15 | 6 | 10 | RM5 | RM6/7 | RM9 |

| 100 | 6,8,10,12,15 | 6 | 10 | RM5 | RM6/7 | RM9 |

| 125 | 6,8,10,12,15 | 6 | 10 | RM5 | RM6/7 | RM9 |

| 150 | 6,8,10,12,15 | 6 | 10 | RM5 | RM6/7 | RM9 |

| 175 | 6,8,10,12,15 | 6 | 10 | RM5 | RM6/7 | RM9 |

Other dimensions available on request – Please indicate required T and X

“H” central holes avilable: Ø20mm Ø31.75mm H6

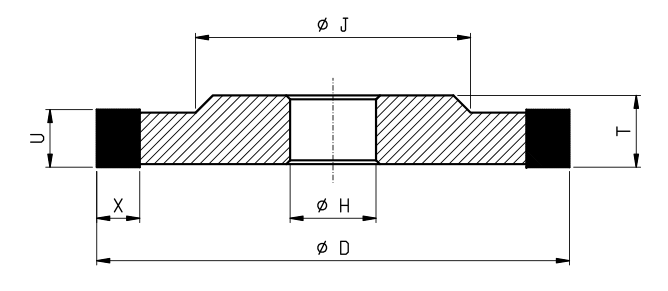

3A1 14A1

| D | U | X=6mm | X=10mm | Diamond | CBN | |

| 50 | 2,4,5 | 6 | RM5 | RM9 | ||

| 50 | 6,8,10 | 6 | 10 | RM5 | RM6/7 | RM9 |

| 75 | 2,3,4,5 | 6 | RM5 | RM9 | ||

| 75 | 6,8,10,12,15 | 6 | 10 | RM5 | RM6/7 | RM9 |

| 100 | 2,3,4,5 | 6 | RM5 | RM9 | ||

| 100 | 6,8,10,12,15 | 6 | 10 | RM5 | RM6/7 | RM9 |

| 125 | 2,3,4,5 | 6 | RM5 | RM9 | ||

| 125 | 6,8,10,12,15 | 6 | 10 | RM5 | RM6/7 | RM9 |

| 150 | 2,3,4,5 | 6 | RM5 | RM9 | ||

| 150 | 6,8,10,12,15 | 6 | 10 | RM5 | RM6/7 | RM9 |

| 175 | 6,8,10,12,15 | 6 | 10 | RM5 | RM6/7 | RM9 |

Other dimensions available on request – Please indicate required U and X

“H” central holes avilable: Ø20mm Ø31.75mm H6

Other central holes avilable on request

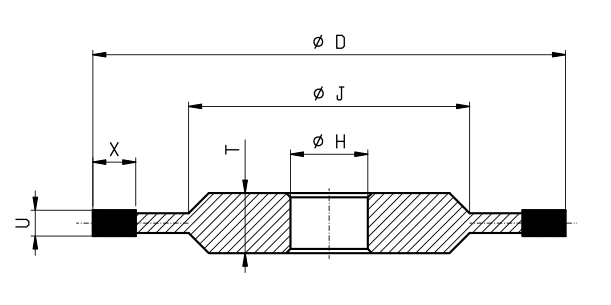

1V1

| D Ø | T | X | X | Diamond | CBN | |

| 50 | 6,8,10 | 6 | 10 | RM5 | RM6/7 | RM9 |

| 75 | 6,8,10,12,15 | 6 | 10 | RM5 | RM6/7 | RM9 |

| 100 | 6,8,10,12,15 | 6 | 10 | RM5 | RM6/7 | RM9 |

| 125 | 6,8,10,12,15 | 6 | 10 | RM5 | RM6/7 | RM9 |

| 150 | 6,8,10,12,15 | 6 | 10 | RM5 | RM6/7 | RM9 |

| Special 175 | 6,8,10,12,15 | 6 | 10 | RM5 | RM6/7 | RM9 |

| Special 200 | 6,8,10,12,15 | 6 | 10 | RM5 | RM6/7 | RM9 |

Other dimensions available on request – Please indicate required T and X

“H” central holes avilable: Ø20mm Ø31.75mm H6

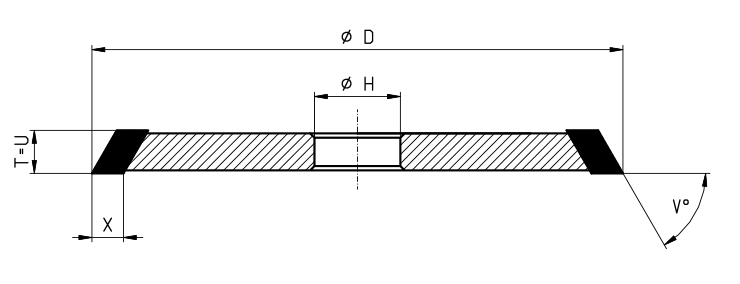

3V1 14V1

| D | U | X=6mm | X=10mm | Diamond | CBN | |

| 50 | 2,4,5 | 6 | RM5 | RM9 | ||

| 50 | 6,8,10 | 6 | 10 | RM5 | RM6/7 | RM9 |

| 75 | 2,3,4,5 | 6 | RM5 | RM9 | ||

| 75 | 6,8,10,12,15 | 6 | 10 | RM5 | RM6/7 | RM9 |

| 100 | 2,3,4,5 | 6 | RM5 | RM9 | ||

| 100 | 6,8,10,12,15 | 6 | 10 | RM5 | RM6/7 | RM9 |

| 125 | 2,3,4,5 | 6 | RM5 | RM9 | ||

| 125 | 6,8,10,12,15 | 6 | 10 | RM5 | RM6/7 | RM9 |

| 150 | 2,3,4,5 | 6 | RM5 | RM9 | ||

| 150 | 6,8,10,12,15 | 6 | 10 | RM5 | RM6/7 | RM9 |

| 175 | 6,8,10,12,15 | 6 | 10 | RM5 | RM6/7 | RM9 |

Other dimensions available on request – Please indicate required U and X

“H” central holes avilable: Ø20mm Ø31.75mm H6

Other central holes avilable on request