Cylindrical Grinding

The cylindrical grinder is a type of grinding machine used to shape the outside of an object. The cylindrical grinder can work on a variety of shapes; however the object must have a central axis of rotation. This includes but is not limited to such shapes as a cylinder, an ellipse, a cam, or a crankshaft. [1]

Cylindrical grinding is defined as having four essential actions:

- The work (object) must be constantly rotating

- The grinding wheel must be constantly rotating

- The grinding wheel is fed towards and away from the work

- Either the work or the grinding wheel is traversed with respect to the other.

Toolgal developed a special Phenol bond, part of its bond’s family CB4 for the cylindrical grinding

Diameter – Up to 450mm

Toolgal’s wheels apply successfully on all STUDER Grinding Machines

Diamond grit sizes: D20 Micron for a special finishing up to D181 for rough grinding and fast material removal

Request a sample or Information

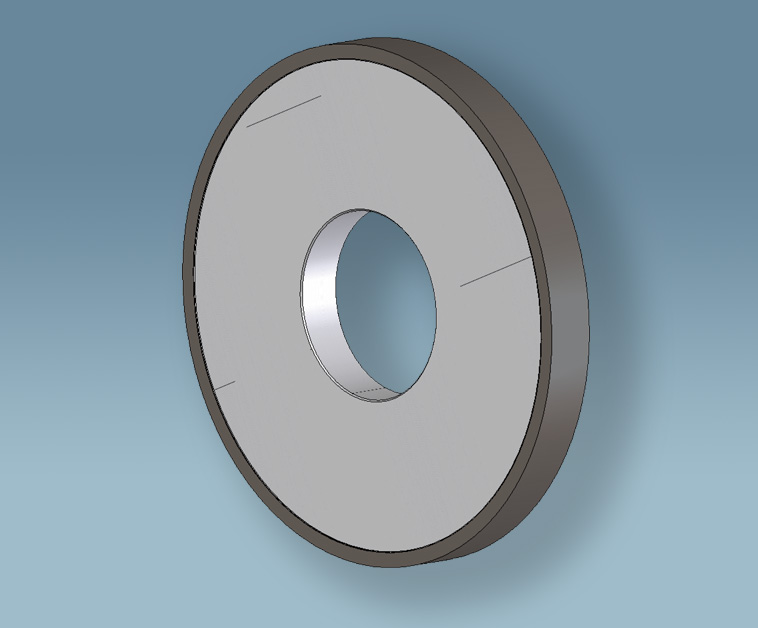

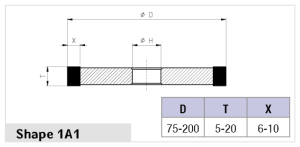

1A1

| 1A1 | Bonds avilable | ||

| D Ø | T | X | Diamond |

| Special 175 | 6,8,10,12,15 | 6 | CB4 |

| Special 200 | 6,8,10,12,15 | 6 | CB4 |

| special 250 | 6,8,10,12,15 | 6 | CB4 |

| Special 305 | 6,8,10,12,15 | 6 | CB4 |

| Special 350 | 6,8,10,12,15 | 6 | CB4 |

| Special 400 | 6,8,10,12,15 | 6 | CB4 |

| Special 500 | 6,10,12,15 | 6 | CB4 |

Other dimensions available on request – Please indicate required T and X

Downloads: